Digital Supply Chain Trends in 2023

We can all agree that change is nothing new in the supply chain industry. The history of logistics has been a story of change – a tale of high tides and intelligent sailing.

Digitalization, however, has only taken the logistics industry by storm in the past few decades. Thanks to the rapid adoption of digital technologies, the way of managing and moving goods within the supply chain is changing for the better.

Be it automated inventory, routing, and record-keeping, or the combined power of the cloud, big data, and Industrial Internet of Things (IIoT) – digitalization enables companies to better respond to the ever-evolving demands of the market and its drivers.

That said, it is important to note that not all logistics providers have undertaken or understand the benefits of technology. According to extensive research by Zippia, 69% of cargo providers do not have total visibility. Only 6% of companies experience full visibility.

A long way to go, but the trends point towards acceleration. And thus, we can board the ship of 2023 with a positive outlook.

In this article, we look at what happened in the supply chain industry in 2022, and how emerging digital trends will help to solve them in 2023.

Read ahead:

- What factors promote supply chain digitalization?

- Changing buying habits

- Competitive market

- Complexity of globalization

- Global Supply Chain in 2022: What happened?

- What are the top supply chain digital trends for 2023?

- Blockchain in logistics

- Supply chain digital literacy

- AI, IoT, Robotics, and Automation in the supply chain

- Need for 5G in the supply chain

- How to leverage supply chain digital trends in 2023?

What factors promote supply chain digitalization?

It is a misconception that the coronavirus pandemic changed everything. Digitalization in the supply chain began much earlier but was taking its own time.

COVID-19 showed up without notice, ripped apart the curtains, caught the logistics industry lagging, and said:

“You lot have no choice but to speed up your digital transformation. Do it now, or go home, go safe.”

So yes, the global pandemic was merely a catalyst. And many other factors have driven and continue to drive the adoption of digital tools in supply chain management.

1. Changing buying habits

The buying habits, especially that of the Millenials and Gen-Zs, have higher expectations compared to the previous generations. They are tech-savvy and use the internet and mobile phones to research before making a purchase.

Moreover, the need for personalization is on the rise. People prefer having their partner’s names on gifts, rather than choosing from existing palletized products. They have different packaging requirements. Not to forget that they want it delivered fast.

Businesses that can meet these expectations by adopting new technologies and processes are more likely to prevail. And they will be better positioned to compete in an increasingly digitalized market.

Additionally, using digital tools and technologies can help businesses easily implement sustainability and social responsibility into their supply chain management practices, which is increasingly important to younger generations.

2. Competitive market

Today’s global market is experiencing intense competition. With rapid technological advancement, and changing consumer preferences, companies have to be creative. It may be to sustain their existing market share or increase their customer base with a timely product that people are looking for.

Another way companies are trying to create an advantage in the market is by shortening the product lifecycle. Doing this creates opportunities to build a brand that keeps up with the latest technology. Moreover, a shorter lifecycle saves time and resources spent on research and development, marketing, and operational costs. Which, in turn, saves a lot of money.

All of this makes a good case for better demand forecasting. And using digital tools to predict and analyze demand only helps logistics businesses sail smoothly in this competitive market.

3. Complexity of globalization

Globalization helps logistics providers access and leverage the global labor market.

But isn’t that a good thing, you ask?

Well, it is, but here’s a simple example to explain its complexity.

A company is building product A by compiling the components B, C, and D. One or all of these components are assembled using other smaller components. So, A reaching the market depends on how effectively B, C, and D reach the final assembly point.

Moreover, this company outsources some of its components from different countries. And therefore their business is heavily reliant on foreign labor.

The problem, however, arises when regional political unrest, natural disasters, and even military operations go south. Such unexpected disruptions will be detrimental to delivering products or services as promised.

The solution is to implement full visibility and enhance communication across partner companies and vendors. By using digital tools, companies can take proactive steps to minimize business downtown while meeting demands.

Global Supply Chain in 2022: What happened?

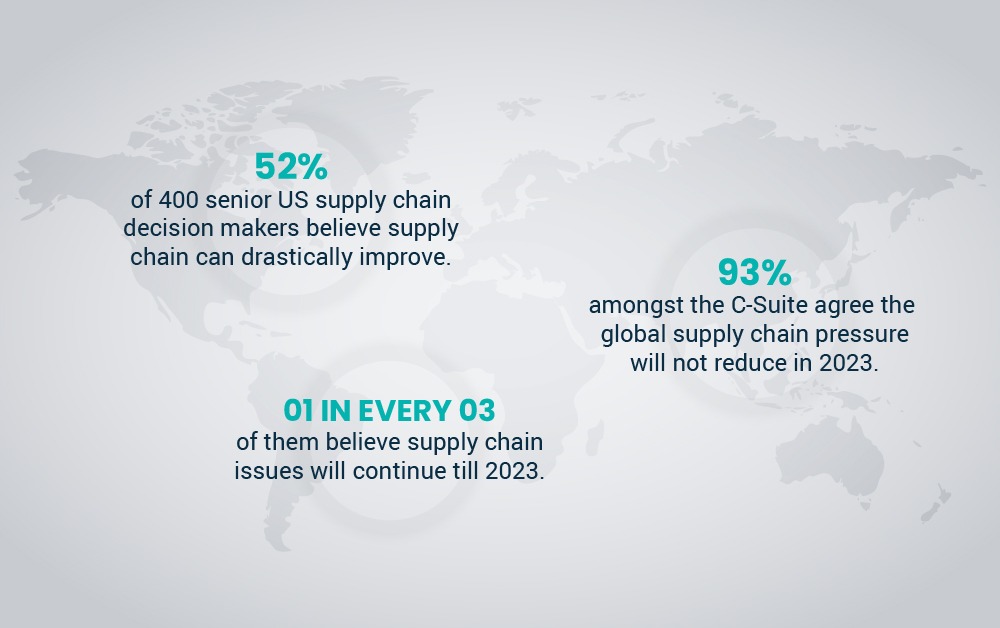

Systemanalyse Programmentwicklung (SAP) conducted a new survey with 400 U.S. senior supply chain decision-makers in early September 2022. According to the results, 52% think their supply chain can improve drastically. One in three of them expects the issues to continue until summer 2023, at least.

Interestingly, another supply chain disruption study by Logistics Management reports a similar mindset among their C-suite readers. The survey finds that more than 93% of the respondents “strongly or somewhat agree” that 2023 will not magically release the global supply chain pressure.

The global supply chain in 2022 had to fight disruptions, shortages or unmet demand, rising fuel costs, and port congestion. It shows in numbers too and will be the main focus going forward in 2023.

.

What are the top supply chain digital trends for 2023?

According to the research by SAP, 72% of the respondents plan to adopt new technology. They believe that doing so will help them to overcome their supply chain challenges easily.

Here’s a compilation of new digital trends that can elevate logistics businesses in their pursuit to conquer the year 2023.

01. Blockchain in logistics

Blockchain technology provides a secure and transparent way to track goods as they move through the supply chain. Transparency is a major pro for payment tracking too.

The decentralized nature of a blockchain ensures that all parties in the supply chain have access to the same information. The database structure enables end-to-end transparency.

Additionally, the use of smart contracts on a blockchain allows for automated tracking and execution of contractual agreements, which can further increase efficiency and reduce the need for manual work.

Overall, the use of blockchain in the supply chain can improve traceability, reduce costs, and increase trust among the parties involved.

02. Supply chain digital literacy

Employee burnout and retention rate have been a plague to logistics providers. Especially for businesses still dependent on traditional operations. Employees don’t get enough space to increase their knowledge and become versatile as they sink into paperwork and tiring jobs.

To provide space for career development, companies may try to improve digital literacy within their workforce. When mundane tasks are overtaken by automated processes, real talent can be used to do more meaningful work. This will boost employee satisfaction, and make them feel like they are contributing to the company’s growth.

Without proper knowledge and myth-busting, workers could be worried about their job security. It is the responsibility of the leadership team to educate them and train them to increase efficiency using new technology.

PWC’s 2022 survey suggested that 19% of companies will focus on digital upskilling and reskilling of the existing workforce. In 2023, we can expect this figure to grow exponentially in a bid to promote agility within the organization.

03. AI, IoT, Robotics, and Automation in supply chain

Artificial intelligence (AI), the Internet of Things (IoT), and automation can all be leveraged to improve supply chain management.

AI and machine learning can be used to analyze current data and make predictions about future demand. This will allow companies to optimize their production and inventory levels. AI can also be used to optimize transportation routes and identify bottlenecks in the supply chain.

IoT can be used to track the location and condition of goods as they move through the supply chain. Sensors can be placed on shipments to collect data on temperature, humidity, and other factors that could affect the quality of the goods. This information can then be used to optimize the supply chain and ensure that goods are handled and transported as efficiently and effectively as possible.

Automation, such as the use of robots can help to streamline various processes within the supply chain. For example, they can be used to handle the packing and sorting of goods, reducing the need for manual labor and increasing efficiency.

Allied Market Research released a study on the logistics automation market in April 2022. With a value of $49.7 billion in 2020, it is projected to almost triple by the year 2030. This means that we can see a substantial acceleration on the automation front in 2023.

04. Need for 5G in supply chain

5G brings significant improvements in terms of speed, reliability, and capacity compared to previous generations of mobile networks.

5G will enable real-time tracking and communication within the supply chain. As globalization combines organizations, there is a need for smooth and faster connectivity.

With low latency and high-speed connections, it would be possible for all parties in the supply chain to access and share information in near real time, enabling more efficient and effective collaboration.

Additionally, 5G enables new technologies such as augmented reality (AR) and virtual reality (VR). For example, AR could be used to provide training and support to workers in remote locations, and even improve warehouse management. And VR could be used for product demonstrations and other purposes.

How to leverage supply chain digital trends in 2023?

As mentioned earlier, the supply chain has constantly been subjected to chaos. To stay afloat, logistics companies have to be smarter than ever before.

Learning, understanding, and implementing digital solutions should be a priority. Digitalization will help your company stay clear of icebergs and roadblocks along your business journey.

At SFL, we believe in digitally elevating your supply chain business. As our CEO and founder Ikraam Reyaz likes to say,

“We want to help our customer and their customer. We’re here to simplify complex supply chain issues using our technology and domain expertise.”

Do you want to elevate your logistics business digitally? Book a call with one of our experts for free no